The Future of 3D Printing in Construction: BIM as a Catalyst

Introduction: Transforming Construction with 3D Printing and BIM

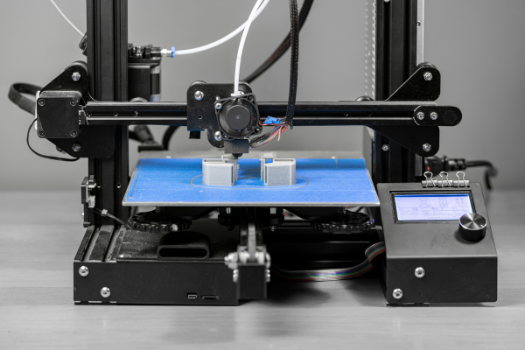

3D printing is changing how we build, offering new ways to improve construction efficiency, design flexibility, and sustainability. This technology can speed up construction and create complex structures that were difficult or costly to produce before. But for 3D printing to reach its full potential, it needs a strong foundation of collaboration and precision—and that’s where Building Information Modeling (BIM) comes in.

BIM brings together all aspects of a construction project in a centralized digital model. It allows teams to work together seamlessly, improving project tracking, resource allocation, and construction scheduling. By combining BIM with 3D printing, construction professionals can achieve better project control, reduce costs, and enhance construction productivity. This powerful synergy is setting the stage for a new era in construction, where innovative tools work together to drive efficiency and support sustainable practices.

The Role of BIM in 3D Printing: Bridging Design and Reality

BIM plays a critical role in connecting design and reality in 3D printing for construction. It acts as a central framework, bringing together architects, engineers, and contractors to work in real-time. With BIM, each team member can access a shared digital model, enabling easy collaboration and quick adjustments. This model serves as a single source of truth for everyone involved, enhancing project tracking and reducing errors.

One of BIM’s biggest strengths is in visualization and planning. Through the digital model, teams can visualize complex designs before construction begins. This clarity helps in spotting potential issues early, saving time and resources. BIM also aids in material optimization, providing accurate cost estimation and minimizing waste. By understanding exact material needs, teams can plan better, control construction budgets, and improve project efficiency.

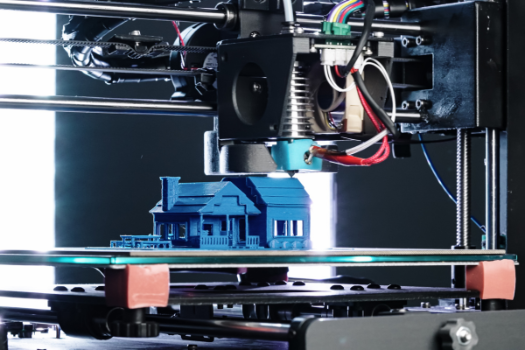

In projects that combine 3D printing with BIM, we see clear improvements in construction workflows and project milestones. The data-driven nature of BIM helps to create a precise roadmap, making it easier to manage compliance, monitor real-time tracking, and streamline document control. In short, BIM bridges the gap between design and execution, turning ambitious 3D-printed structures into reality with increased speed and reduced costs.

Emerging Trends in 3D Printing for Construction

The construction industry is witnessing exciting trends in 3D printing that are reshaping how projects are executed. One key trend is on-site 3D printing, which allows teams to build structures directly at the construction site. This approach reduces transportation costs and speeds up project timelines, making it a game-changer for project tracking and resource allocation.

Automation is also playing a big role in 3D printing for construction. With advanced robotics, 3D printers can operate with minimal human intervention, improving both speed and precision. This automation integrates seamlessly with BIM, allowing for streamlined workflows that adapt in real-time. By connecting BIM with automated 3D printing, teams can respond to changes quickly, enhancing project efficiency and controlling costs.

Advancements in materials are further pushing the boundaries of 3D printing. From eco-friendly composites to durable concrete mixes, new materials are expanding design possibilities while supporting sustainability goals. With BIM guiding material use and cost estimation, these materials can be optimized for each project’s needs, reducing waste and improving budget management.

These trends showcase a future where 3D printing and BIM come together to create customizable, efficient, and cost-effective construction projects, paving the way for faster, more innovative building solutions.

Sustainability and 3D Printing: Paving the Way to Greener Construction

3D printing is opening up sustainable pathways in construction by reducing waste and promoting the use of recyclable materials. Traditional construction often generates excess waste, but 3D printing allows for precise material use, leading to less waste on-site. This efficiency not only reduces costs but also lowers the project’s carbon footprint, supporting construction’s shift toward greener practices.

BIM plays an essential role in amplifying this sustainability. Through accurate material calculations and resource planning, BIM enables teams to optimize materials down to the smallest detail. This means less surplus and better compliance with environmental standards. By integrating BIM with 3D printing, construction projects can achieve higher levels of efficiency and sustainability, using only what is needed.

Together, BIM and 3D printing set new benchmarks for environmentally friendly construction. This combination is paving the way for a future where building processes are not just efficient but also deeply aligned with sustainability goals, offering a greener choice for the industry.

BIM and 3D Printing in Affordable Housing Solutions

BIM and 3D printing are emerging as powerful tools to address affordable housing shortages, particularly in densely populated areas. The process begins with BIM, where architects and engineers create a precise digital model of a housing unit. This model includes every detail needed for efficient construction, from cost estimation to material use. By optimizing resources, BIM ensures that projects stay within budget, making affordable housing more attainable.

When combined with 3D printing, this digital model can be quickly transformed into real structures. 3D printing allows for the mass production of homes in a fraction of the time required for traditional building methods. This speed and efficiency lower construction costs, making housing more affordable and accessible to a larger population. By controlling project milestones and real-time tracking through BIM, teams can also better manage timelines, ensuring that housing projects are completed quickly and efficiently.

This synergy between BIM and 3D printing represents a compelling solution to global housing challenges. It provides a way to build durable, cost-effective housing at scale, offering hope for affordable housing in areas where demand is high. Together, these technologies pave the way for a future where affordable, quality housing is within reach for more people.

Challenges and the Road Ahead

Adopting BIM and 3D printing in construction comes with challenges. High initial costs, including investment in advanced equipment and training, can deter companies. Additionally, regulatory issues pose hurdles, as building codes and standards often lag behind technological advancements. These factors can slow down adoption, especially for smaller firms with limited budgets.

However, the industry is making progress. Technological advancements are gradually reducing costs, and governments are beginning to adapt regulations to support innovation in construction. For example, some regions are updating building codes to accommodate 3D-printed structures, helping to clear a path for broader adoption. Industry leaders are also investing in training and collaboration tools, making these technologies more accessible.

Though challenges remain, ongoing efforts in technology and policy show a promising road ahead. With continued support, BIM and 3D printing are poised to become central to construction, transforming workflows and setting new standards in project efficiency and sustainability.

Conclusion: The Future of BIM and 3D Printing in Construction

BIM and 3D printing are transforming construction by enhancing collaboration, efficiency, and sustainability. Together, they streamline project tracking, optimize resource allocation, and support sustainable building practices, all while reducing costs and improving construction productivity. From affordable housing solutions to eco-friendly materials, these innovations are making construction more adaptable and responsive to modern needs. As technological advancements continue, BIM and 3D printing are set to reshape the industry, offering a future where construction is smarter, faster, and greener. Embracing these tools today paves the way for a more efficient and responsible construction landscape tomorrow.